Grease Steel-2

Long Life High load caring Grease

High-performance specialty grease SVD Energy Pvt Ltd Grease Steel-2 Is designed to extend the service life of the bearings in a heavy-duty application and elevated temperature. This grease matches the rugged service requirements of rolling mills. Load-carrying and antiwear capabilities of these grease along with high performance are the superior load-carrying/ antiwear characteristics and excellent water resistance to cold and hot water are a result of chemical additives. These additives are dispersed uniformly throughout the grease attributing.

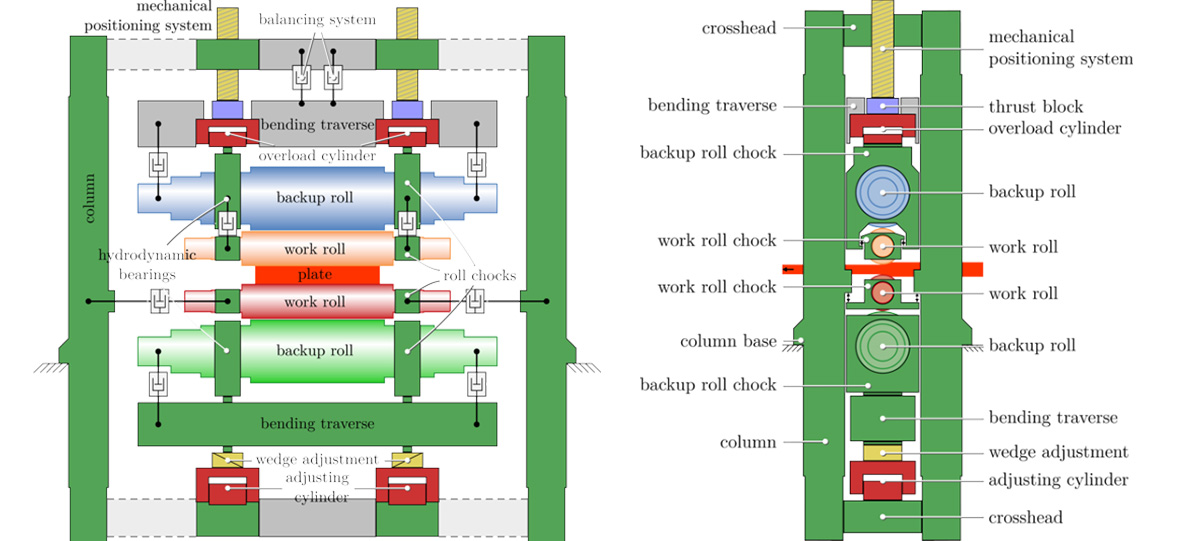

Steel Plants encounter one of the most severe application regimes as far as lubrication is concerned. In the rolling process, the space setting between rollers is reduced after each consecutive pass of the sheets. The bearings must, therefore, tolerate high initial impact loading and must then sustain loading over long time periods as the sheets are thinned to a final prescribed dimension. over long time periods as the sheets are thinned to a final prescribed dimension.

High-performance specialty grease SVD Energy Pvt Ltd Grease Steel-2 Is designed to extend the service life of the bearings in a heavy-duty application and elevated temperature. This grease matches the rugged service requirements of rolling mills. Load-carrying and antiwear capabilities of these grease along with high performance are the superior load-carrying/ antiwear characteristics and excellent water resistance to cold and hot water are a result of chemical additives. These additives are dispersed uniformly throughout the grease attributing.

Steel Plants encounter one of the most severe application regimes as far as lubrication is concerned. In the rolling process, the space setting between rollers is reduced after each consecutive pass of the sheets. The bearings must, therefore, tolerate high initial impact loading and must then sustain loading over long time periods as the sheets are thinned to a final prescribed dimension. over long time periods as the sheets are thinned to a final prescribed dimension.

Product Description

Lubrication in an integrated steel plant is a major challenge with numerous types of lubricants and various types of equipment. The steel plant equipment work under various operating parameters, like from extreme heavy load to very high speed, low temperatures to high temperatures, dusty polluted environment to humid acid environment. Therefore a proper selection of lubricant is much essential for smooth operation in steel plants and the reliability of equipment.

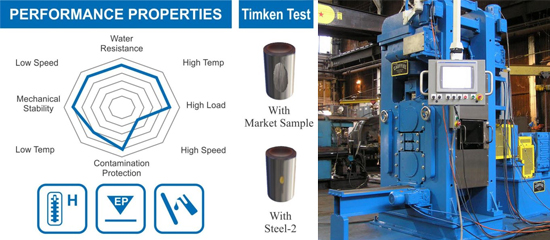

A Water Resistant, High Load bearing premium quality grease was developed with required performance criteria. This is specially formulated to meet the demand for severe water washout and Awgrease for boundary lubrication. This grease is recommended for both plain and anti-friction bearings for a wide variety of applications such as automotive and industrial applications. It is preferred for steel mill lubrication under high load and high water wash-out conditions

A Water Resistant, High Load bearing premium quality grease was developed with required performance criteria. This is specially formulated to meet the demand for severe water washout and Awgrease for boundary lubrication. This grease is recommended for both plain and anti-friction bearings for a wide variety of applications such as automotive and industrial applications. It is preferred for steel mill lubrication under high load and high water wash-out conditions

Additional Information

| Color |

Visual, Blue |

|---|---|

| Appearance |

Smooth & Buttery |

| Type of soap |

Actual , Mix complex thickener |

| NLGI Grade |

ASTMD 217 / DIN 51818 , 2 |

| Operation temperature Range °C |

-10 to > 200°C |

| Four ball weld load N/Cm2 |

IP – 239 , 6000 |

| Dropping Point °C |

NFT 60 – 627,280 °C |

| K. Viscosity of base oil at 40 °C mm2/s(cSt) |

ASTM D445 , 220 / 460 Cst |

| Timken ok load, is |

Timken, 60 |

| Water wash out |

1% Max. |