Grease HT-2

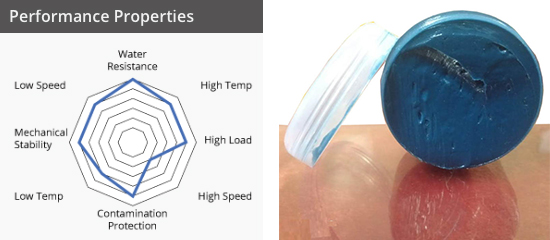

High level of shear stability because AW and EP additives give high-temperature grease SVD Energy Pvt Ltd Grease HT-2 a long life and its basic structure of mix complex thickener gives it high-temperature stability.

Grease is a semi-solid product of dispersion of a thickening agent in a liquid lubricant together with additives that give special properties. The structure of the grease allows the lubricant to remain in a solid-state until the shear stress between the surface reaches a certain level and grease begins to flow.

Grease is a semi-solid product of dispersion of a thickening agent in a liquid lubricant together with additives that give special properties. The structure of the grease allows the lubricant to remain in a solid-state until the shear stress between the surface reaches a certain level and grease begins to flow.

Product Description

How to Select a High-Temperature Grease

Follow these steps when selecting a high-temperature grease:

Follow these steps when selecting a high-temperature grease:

- Determine the real temperature range. The operating temperature may be less than what it seems. Use contact or non-contact sensor to measure the operating temperature of the grease.

- Is it intermittent or continuous? If it is continuous, then look for a top-tier product that meets the operational requirements.

- Do heating and cooling cycles accompany machinery operating and non-operating intervals? Consider if moisture may be induced through either atmosphere or impingement.

- What is the reasonable relubrication interval or opportunity? If relubrication is going to be difficult, then consider a top-tier product to achieve a lower use cost even though it’s more expensive.

- Consider any cosmetic issues. Can the product drip onto a component in the process? Relubrication frequency and volume must be balanced against product contamination issues.

Additional Information

| Color |

Visual, Blue |

|---|---|

| Appearance |

Smooth & Buttery |

| Type of soap |

Actual , Mix complex thickener |

| NLGI Grade |

ASTMD 217 / DIN 51818 , 2 |

| Operation temperature Range °C |

-20 to > 260°C |

| Four ball weld load N/Cm2 |

IP – 239 , 6000 |

| Dropping Point °C |

NFT 60 – 627 , 318 °C |

| K. Viscosity of base oil at 40 °C mm2/s(cSt) |

ASTM D445 , 220 / 460 Cst |

| Timken ok load, is |

55 |

| Water wash out |

1% Max. |